FEATURED PROJECTS

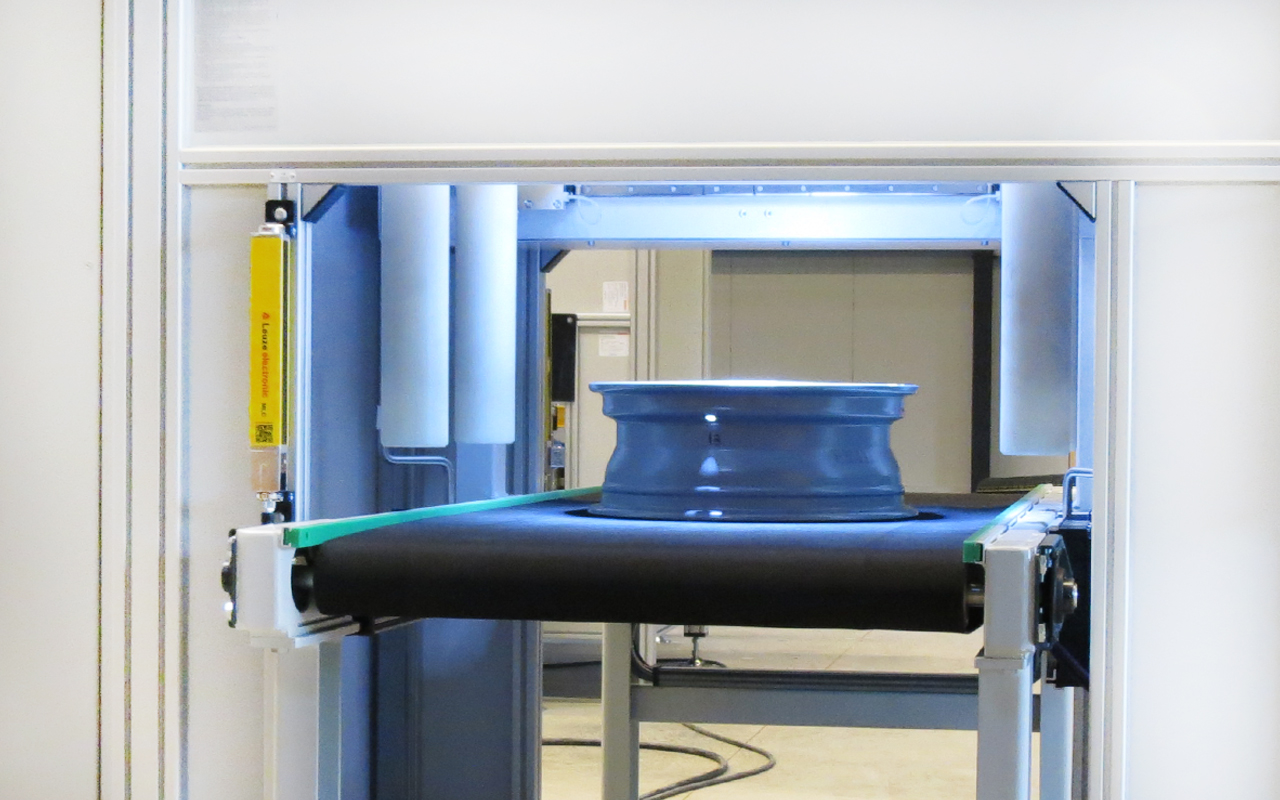

WHEEL & TYRE MATCHING MACHINE

This machine is used to automatically match fresh soaped pre-assembled wheels, using the Match Point detection system. The system automates the tyre and rim assembly process, ensuring quality control.

The markings of radial force high point of the tyre and geometrical low point of the wheel rim can be detected and the necessary rotation angles integrated into the machine.

Alternatively, the geometrical low point of the rim can be measured in a previous manual process and then passed to the matching machine.

The tyre mounted on the rim, soaped and pressure less, is pressed into the well of the rim. The rim can be turned to the previously determined offset angle. After this process the reference points are checked by the camera system, to ensure they are matching and in the necessary tolerance.

SPECIALISING IN WHEEL AND TYRE MATCHING TECHNOLOGIES

We are a trusted and respected supplier of tyre and wheel matching technology, with installation bases in over 26 locations globally. Using innovation and advanced solutions, we continue to support the industry’s most prestigious tyre and wheel assemblers. From conception to completion, we will assist you in developing and delivering a custom tyre and wheel assembly process.

PAST PROJECTS

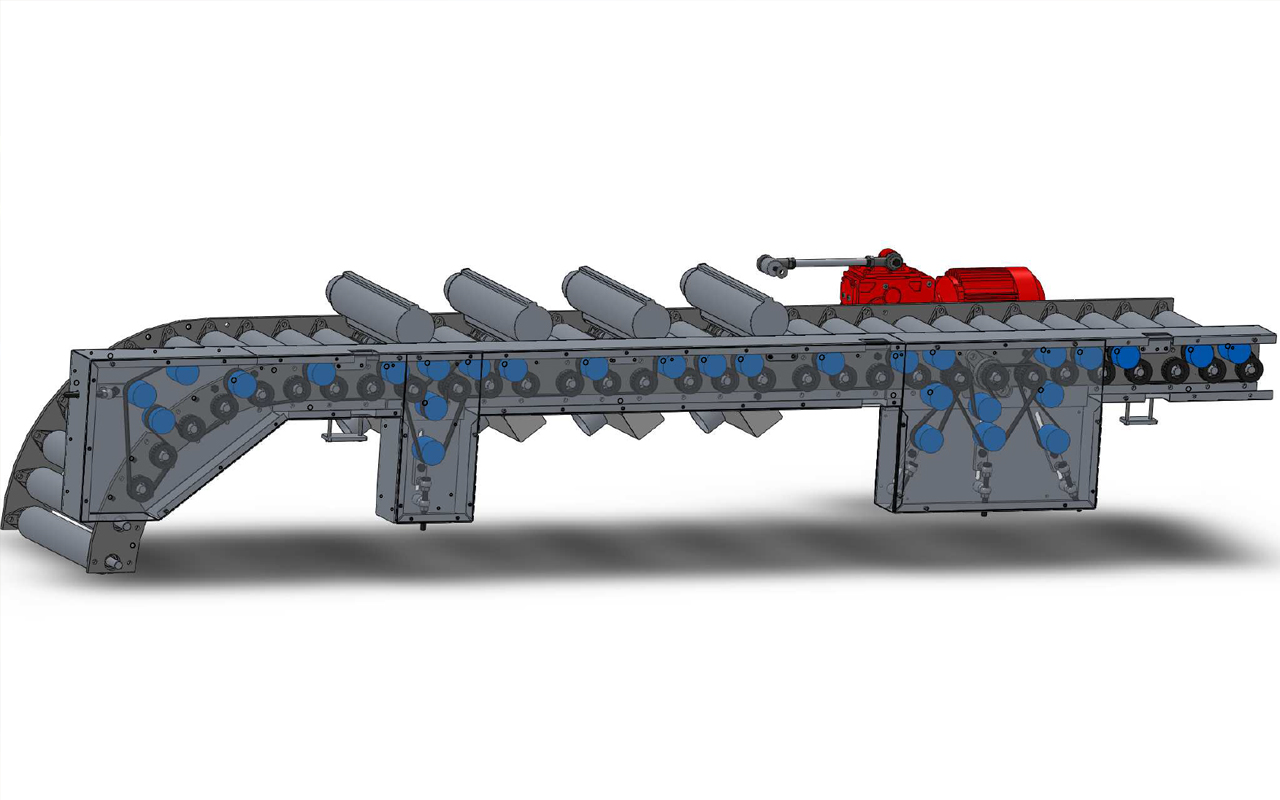

TYRE RECOGNITION STATION

At the beginning of the line, tyres are selected and transported to the process machines.

Before heading to these machines, the tyres are controlled for the correct Type by 6 different characteristics of the tyres.

When the value are not corrected, the Tyre Recognition Station would stops the transportation and reverses the tyres for reject or further examination.

The values are recorded and displayed in a diagram.

AUTOMATIC COLOUR RECOGNITION STATION FOR TREADS FOR TYRES

Different color stripes are applied to a tyre tread with a contactless or contact system.

Up to 5 stripes with different colors can be applied at a predetermined distance from each other and to the center of the tread.

A camera system, which is located above the tread, now checks up to 6 different possibilities of the current treat with the colour strips.

The values are communicated to the color system and deviations are corrected immediately.

The values are recorded and displayed in a diagram.

RIM RECOGNITION STATION

At the beginning of the line, rims are selected and transported to the process machines.

Before heading to these machines, the rims are controlled for the correct Type by 4 different characteristics of the rims.

The Rim Recognition Station would stops the transportation and reverses the rim for reject or further examination when the values are not correct.

The values are recorded and displayed in a diagram.

DRYING SYSTEM WITH AIR BLADES